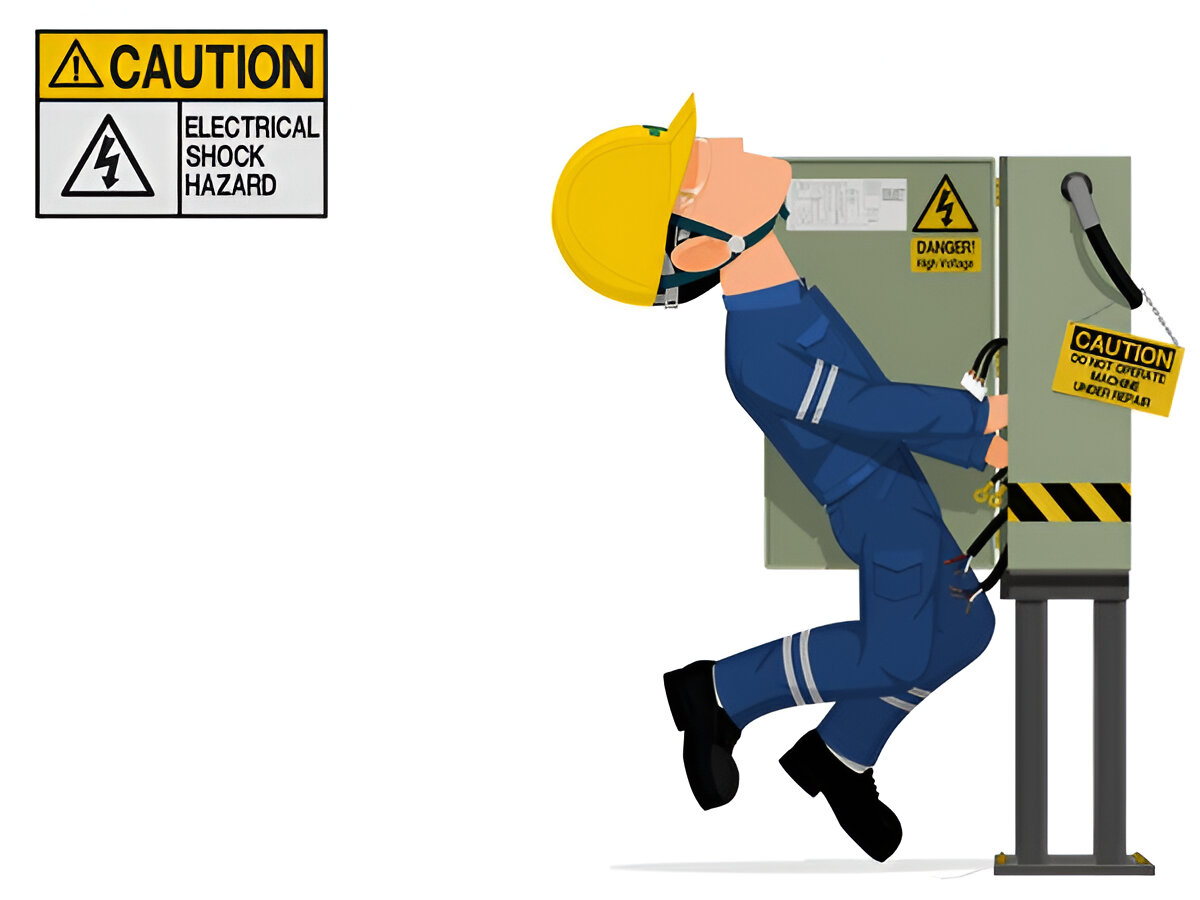

When it comes to electrical systems—whether in residential homes or commercial properties—safety should never be an afterthought. Electrical hazards are not only dangerous but also potentially deadly if ignored or mishandled. One of the most overlooked yet critical components of electrical safety is the proper use of safety labels and tags. These seemingly simple tools serve as vital warnings, helping prevent accidents, injuries, and property damage.

Why Are Electrical Safety Labels and Tags So Important?

Electrical safety labels and tags are designed to communicate essential information about equipment, circuits, and potential hazards. Whether it’s a high-voltage warning, arc flash alert, or lockout/tagout notice, these signs help workers and occupants quickly identify risks and follow correct safety procedures.

For example, during electrical repairs near me, technicians rely on clear, visible tags to know which circuits are live or shut off. Without them, even a simple repair could lead to a serious injury—or worse.

Protecting Lives and Property

The primary purpose of safety labeling is to prevent accidents. Labels warn workers and homeowners alike about electrical hazards such as shock risk, burn risk, and equipment malfunctions. For example, if a breaker panel is labeled properly, a technician performing electrical panel clearance work knows exactly what to expect and how to proceed safely.

In commercial environments, where more complex systems are involved, safety labels are even more essential. Large facilities often have a mix of circuits, machines, and components that can easily be confused without proper documentation. Tags prevent mistakes during maintenance or upgrades and are often required by OSHA and NFPA safety codes.

Reducing Liability and Ensuring Compliance

Failing to label electrical systems properly doesn’t just increase the chance of injury—it can also lead to serious legal consequences. Businesses, in particular, must follow strict labeling guidelines or risk fines, shutdowns, and lawsuits. Whether you’re working with commercial electricians or performing in-house maintenance, proper labeling is a non-negotiable.

Even for home projects like ceiling fan installation near me, safety labeling ensures homeowners and future electricians can identify circuits and avoid costly mistakes.

Common Types of Electrical Safety Tags

Electrical tags come in various forms, each serving a specific purpose:

- Warning Labels: Indicate a general electrical hazard or high voltage area.

- Arc Flash Labels: Notify workers about the potential for arc flash explosions and guide proper PPE usage.

- Lockout/Tagout Tags: Used during maintenance to indicate that equipment is de-energized and should not be turned on.

- Circuit ID Tags: Help identify which breaker controls which outlet, light, or appliance—especially useful for electrical circuit tracer work.

How to Implement Effective Safety Labeling

To ensure your electrical systems are clearly labeled:

- Use weather-resistant, durable labels.

- Ensure text is legible and includes key details (voltage, risk level, instructions).

- Keep a consistent format across all tags and labels.

- Update labels when systems are upgraded, such as after an upgrade electrical panel service.

- Train employees or residents to recognize and follow label warnings.

Conclusion

Electrical safety isn’t just about wiring and grounding—it’s also about communication. Proper labeling plays a key role in preventing electrical hazards, protecting workers, residents, and assets from danger. Whether you’re upgrading an outlet, installing a new circuit, or managing a commercial system, never underestimate the power of a well-placed label or tag.

If you’re unsure where to start or need professional help, consider working with qualified commercial electrical contractors to ensure your systems are safe, compliant, and clearly marked.